How can industrial equipment models help engineers save 30% of training costs?

How can industrial equipment models help engineers save 30% of training costs?

In today's rapidly changing technological environment, enterprises are constantly seeking ways to improve production efficiency and reduce costs. As an engineer, have you ever been troubled by expensive training costs?

Industrial Equipment Model: Revolutionaries of Training Efficiency

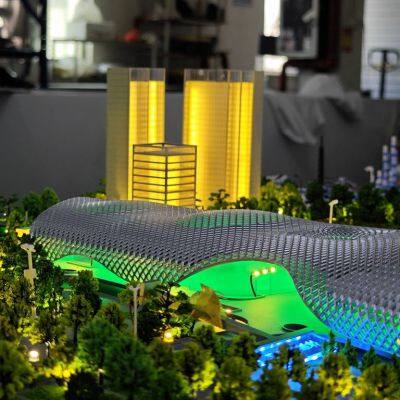

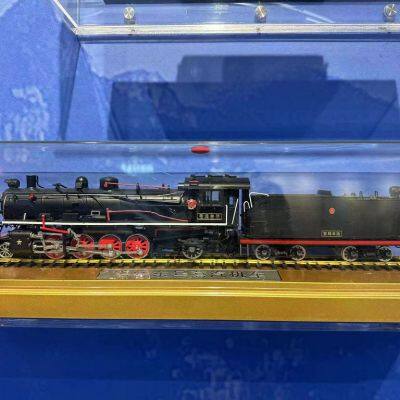

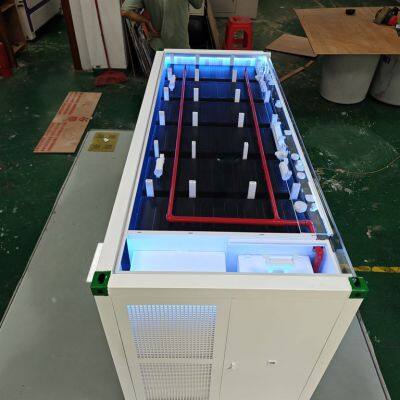

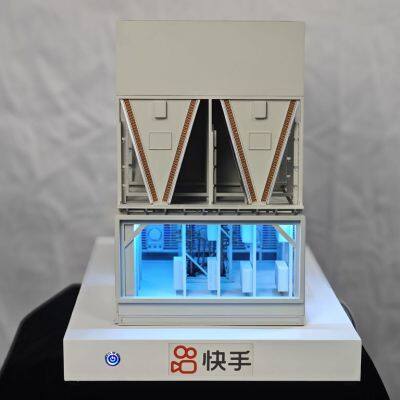

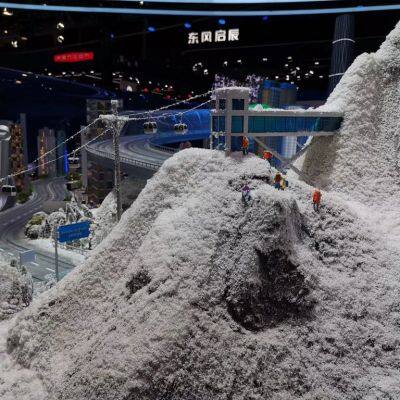

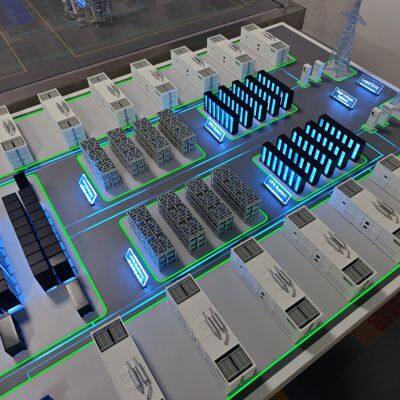

Let's understand what an industrial equipment model is. An industrial equipment model is a virtual or physical replica that can accurately simulate the operation process, functional characteristics, and failure modes of actual equipment. Through these models, engineers can conduct experiments, analysis, and learning without direct contact with physical devices.

Strategy to save 30% of training costs

Reduce on-site operational risks: Training with industrial equipment models can greatly reduce the risk of equipment damage or safety accidents caused by improper operation. This not only protects the equipment, but also ensures the safety of the engineers.

Improve training efficiency: Compared to traditional face-to-face training, using industrial equipment models for training can save a lot of time. Because engineers can practice multiple times on the model until they fully master the required skills.

Reduce training costs: By simulating equipment operations in real work environments, industrial equipment models can help engineers become familiar with new systems faster, thereby shortening the transition period from theory to practice. This means that you can achieve higher work efficiency at lower training costs.

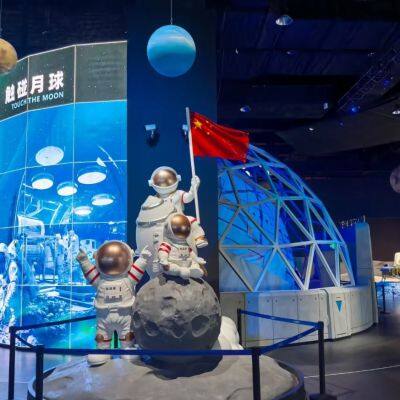

Promoting interdisciplinary learning: Industrial equipment models typically involve knowledge from multiple fields, such as mechanical engineering, electronic engineering, computer science, etc. This interdisciplinary learning approach helps engineers establish a more comprehensive knowledge system and lay a solid foundation for their future career development.

Continuous updating and maintenance: With the development of technology, new industrial equipment is constantly emerging. By using industrial equipment models, engineers can continuously update and maintain their skill sets, ensuring they stay up-to-date with the times.

Conclusion

Industrial equipment models are not only effective tools for improving production efficiency and reducing costs, but also key to helping engineers achieve rapid learning and adaptation to new technologies. By utilizing these models, you can significantly reduce training costs while maintaining sensitivity and adaptability to new technologies. Therefore, investing in industrial equipment models can bring long-term economic benefits and competitive advantages to your business.

Recently Posted

-

The fusion application of digital twin models

September 26, 2025The fusion application of digital twin modelsWith the rapid development of technology, the concept of the metaverse is gradually m Read More

Read More -

Essential for Carbon Neutrality Theme Exhibition: Green Energy Model Customization Guide

September 26, 2025Essential for Carbon Neutrality Theme Exhibition: Green Energy Model Customization GuideWith the increasingly severe global climat Read More

Read More -

How can industrial grade accuracy make models stand out at exhibitions?

September 26, 2025How can industrial grade accuracy make models stand out at exhibitions?In today's technology exhibitions, product display has Read More

Read More -

Dynamic demonstration+intelligent interaction: make your booth model the focus

September 26, 2025Dynamic demonstration+intelligent interaction: make your booth model the focusIn today's era of information explosion, the abi Read More

Read More